Understanding DMAIC in Quality

DMAIC in quality serves as a systematic methodology for **process improvement**, providing a structured approach to solving operational challenges. By combining Lean principles, Six Sigma statistical analysis, and Total Quality Management techniques, DMAIC creates a framework that transforms how you identify, measure, analyze, improve, and control critical processes in your organization.

Key Takeaways:

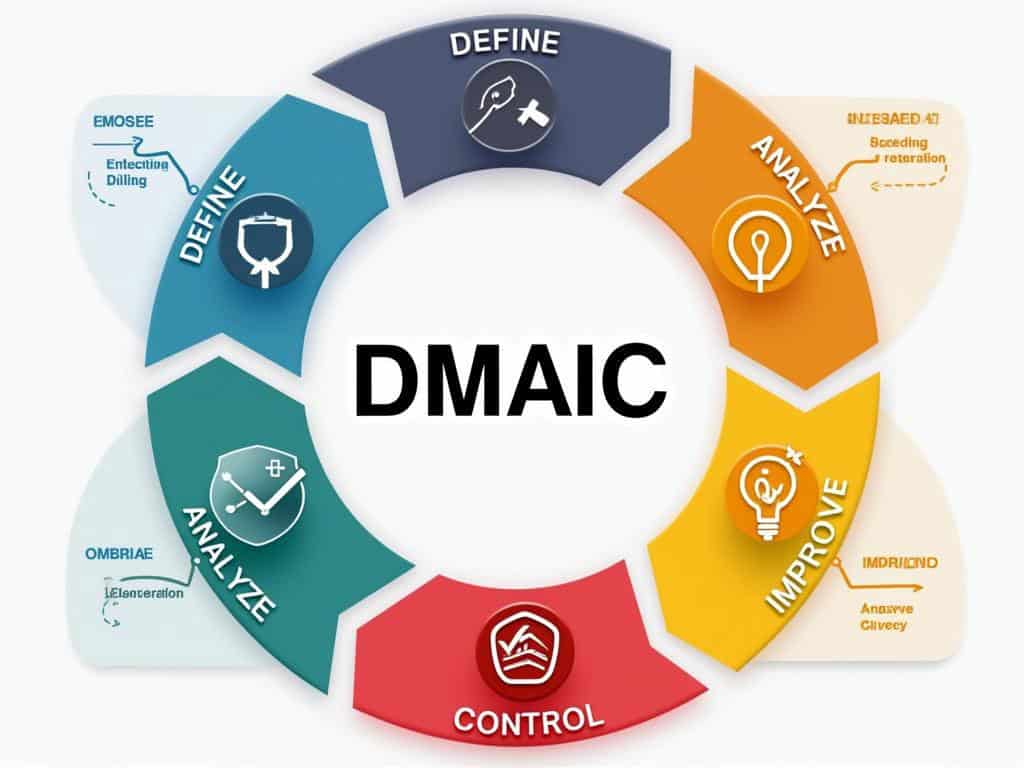

- DMAIC is a five-phase methodology (Define, Measure, Analyze, Improve, Control) designed to systematically improve organizational processes.

- The approach combines statistical analysis, waste elimination, and data-driven decision-making to enhance operational efficiency.

- DMAIC originated from quality management experts and has evolved to be applicable across diverse industries.

- The methodology helps organizations reduce process variation, eliminate defects, and drive continuous improvement.

- Successful DMAIC implementation can lead to significant cost savings and improved customer satisfaction.

Implementing DMAIC Methodology

Implementing DMAIC methodology offers your organization a clear roadmap for tackling process problems. The structured nature of this approach ensures you’ll address issues thoroughly rather than applying quick fixes that don’t last. Each phase builds on the previous one, creating a logical progression from problem identification to sustainable solution.

Many companies find that DMAIC delivers concrete results because it relies on data rather than assumptions. This evidence-based approach eliminates guesswork and helps you pinpoint exactly where improvements will have the greatest impact. The quality improvement process also encourages cross-functional collaboration, bringing together different perspectives to develop more effective solutions.

Versatility of DMAIC

Your team can apply DMAIC to virtually any business challenge that involves a process. From manufacturing to healthcare to financial services, the principles remain consistent while the specific tools adapt to your industry’s needs. The versatility of this framework makes it a valuable addition to your process improvement toolkit, complementing other quality methodologies you might already use.

“In a world where operational challenges abound, DMAIC stands as a beacon of structured problem-solving, blending Lean principles with Six Sigma rigor to transform processes and enhance efficiency. By empowering organizations to methodically define, measure, analyze, improve, and control, this powerful methodology not only drives continuous improvement but also unlocks significant cost savings and elevates customer satisfaction.”

Origins and Evolution of DMAIC

The DMAIC methodology has deep historical roots in quality management principles that continue to shape how organizations approach process improvement today. This powerful framework for applying DMAIC in quality improvement originated from the pioneering work of quality management experts W. Edwards Deming and Walter Shewhart, whose statistical control methods laid the groundwork for modern quality systems.

DMAIC emerged as a fusion of Eastern and Western manufacturing philosophies. It combines elements from the Toyota Production System’s focus on waste elimination with Western statistical process control techniques. This marriage created a comprehensive approach to quality that addresses both efficiency and precision challenges in complex business environments.

The Evolution of DMAIC in Modern Quality Management

As quality management practices evolved, DMAIC in quality became increasingly refined and standardized. The methodology integrates:

- Lean principles focused on identifying and eliminating waste

- Six Sigma’s statistical rigor for reducing process variation

- Total Quality Management’s organizational commitment to excellence

- Statistical Process Control’s data-driven decision making

Over time, DMAIC in quality has expanded beyond its manufacturing origins to transform processes in healthcare, financial services, information technology, and virtually every business sector. This evolution reflects the methodology’s adaptability and effectiveness across diverse operational contexts.

The DMAIC project approach combines the best elements of various quality systems to create a structured pathway for improvement. While initially developed for manufacturing defect reduction, today’s application of DMAIC in quality extends to optimizing customer experience, improving service delivery, and enhancing digital processes.

Organizations increasingly recognize that successful process improvement systems require both analytical rigor and practical implementation strategies. DMAIC provides the framework to balance these needs by guiding teams through each critical phase of improvement work.

The methodology’s evolution also reflects a growing understanding that quality improvement isn’t just about fixing problems but transforming how organizations operate. By implementing DMAIC in quality initiatives, companies can create sustainable competitive advantages through operational excellence.

Today’s DMAIC practitioners benefit from advanced statistical software, digital data collection tools, and collaborative technologies that streamline the improvement process. These technological advancements have made DMAIC in quality more accessible and effective than when it first emerged as a specialized manufacturing discipline.

Organizations that adopt DMAIC can improve process effectiveness by up to 40%, ultimately driving significant cost savings and enhancing customer satisfaction.

hbr.org

Understanding the DMAIC Framework

The DMAIC framework forms the backbone of quality improvement initiatives across industries. This systematic approach to process enhancement incorporates DMAIC in quality methodology to identify, measure, and eliminate defects while reducing process variation. You’ll find this structured method particularly valuable when tackling complex operational challenges.

DMAIC stands for Define, Measure, Analyze, Improve, and Control – five distinct phases that guide your quality improvement journey. This methodology emerged from the pioneering work of W. Edwards Deming and Walter Shewhart, combining elements from the Toyota Production System with Western statistical process control methods. The DMAIC in quality approach blends Lean principles of waste elimination with Six Sigma’s focus on variation reduction to create a comprehensive quality management system.

The Five Phases of DMAIC

The Define phase sets your foundation by clearly identifying problems and opportunities. You’ll create a project charter outlining scope and objectives while using tools like stakeholder analysis and SIPOC (Suppliers, Inputs, Process, Outputs, Customers) mapping. This critical first step in DMAIC in quality ensures your team understands what you’re trying to accomplish and why it matters.

During the Measure phase, you’ll establish baseline performance metrics through careful data collection. This quantitative assessment provides concrete evidence of current process capabilities and sets benchmarks for improvement. Many organizations implement DMAIC projects at this stage to begin tracking critical metrics.

The Analyze phase uncovers root causes behind process issues using statistical tools and methodologies. You’ll employ techniques like:

- Cause-and-effect (Fishbone) diagrams

- Pareto analysis

- Hypothesis testing

- Process capability studies

In the Improve phase, you’ll develop and implement solutions based on your analysis. This often involves brainstorming, Design of Experiments (DOE), and pilot testing to validate proposed changes. The DMAIC in quality approach ensures your improvements are data-driven rather than based on assumptions.

Finally, the Control phase establishes mechanisms to maintain and sustain your improvements. You’ll implement control charts, documentation updates, and training programs to prevent backsliding. Many organizations also adopt continuous improvement practices to build on initial gains.

The DMAIC in quality methodology provides a structured approach that helps you solve complex problems systematically. By following these defined steps, you’ll eliminate guesswork and develop sustainable solutions based on data rather than intuition. This disciplined framework has transformed countless processes across manufacturing, healthcare, finance, and service industries.

Organizations that are able to cultivate a culture of continuous improvement through systematic methodologies like DMAIC can see up to a 30% increase in efficiency in their processes.

hbr.org

Define Phase: Setting the Foundation

The Define phase kickstarts your DMAIC in quality journey by establishing clear boundaries and expectations. This crucial first step determines whether your improvement project succeeds or fails. You’ll need to precisely identify the problem that needs solving and create a comprehensive roadmap for your team.

When initiating the Define phase, you must clearly articulate the issue that’s affecting quality or efficiency. This isn’t simply stating “we need to improve quality” – it requires specific definition of what’s wrong, where it’s happening, and how it impacts your organization. Using DMAIC in quality improvement demands precision from the very beginning.

A well-crafted project charter serves as your team’s guiding document throughout the improvement process. This document should include:

- Problem statement that clearly defines the issue

- Project scope with explicit boundaries

- Business case explaining the value of addressing the problem

- Goals with measurable targets

- Timeline with key milestones

- Team members and their responsibilities

Several powerful tools help you navigate the Define phase effectively. You’ll find stakeholder analysis techniques particularly valuable for identifying everyone affected by the process and the potential improvement. The Voice of the Customer (VOC) matrix captures critical customer requirements, ensuring your quality improvements address what actually matters to end users.

SIPOC Mapping for Process Clarity

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) mapping provides a high-level view of your process. This tool helps you visualize how work flows through your organization and where DMAIC in quality initiatives should focus. Creating a SIPOC map follows these steps:

- Identify all suppliers providing inputs to the process

- List all inputs required for the process to function

- Document the major steps in the process

- Catalog all outputs produced by the process

- Specify customers (internal or external) who receive these outputs

Proper alignment with organizational goals ensures your DMAIC in quality project doesn’t exist in isolation. Connect your project objectives to strategic priorities by consulting with leadership and project leadership to validate that your improvement efforts support broader business aims.

By thoroughly completing the Define phase, you’ll establish a solid foundation for the remaining steps in the DMAIC methodology. This careful preparation helps prevent scope creep and ensures your team stays focused on solving the right problems using DMAIC in quality techniques that drive meaningful results.

Measure Phase: Establishing Baseline Performance

The Measure phase is the critical second step in the DMAIC in quality methodology. You’ll find this phase essential for quantifying current process performance before attempting improvements. During this stage, you’ll develop a comprehensive understanding of how your process currently operates by collecting relevant data.

To effectively execute the Measure phase, you’ll need to follow a structured approach. First, create a detailed data collection plan that clearly identifies what information you need and how you’ll gather it. This ensures your process improvement efforts are built on solid data rather than assumptions.

Collecting accurate process performance metrics is fundamental to DMAIC in quality improvement. You’ll need to:

- Select appropriate measurement systems that deliver reliable data

- Validate your measurement systems through Gage R&R studies

- Gather sufficient data points to establish statistical significance

- Document data collection methods for future reference

- Capture both process inputs and outputs to understand relationships

Statistical tools play a crucial role in this phase. You’ll utilize process visualization techniques like control charts, histograms, and run charts to understand your current process capability. These tools help you identify patterns, trends, and variations that might not be obvious through simple observation.

Establishing Your Performance Baseline

Creating a clear baseline is perhaps the most valuable outcome of the Measure phase in DMAIC in quality improvement. This baseline serves as your reference point for all future comparisons. Without it, you’ll struggle to determine if your improvements are genuinely effective.

The baseline should include key performance indicators (KPIs) relevant to your specific process. For manufacturing processes, this might include defect rates, cycle times, and throughput. For service processes, you might measure response times, error rates, or customer satisfaction scores.

During this phase, you’ll also identify the “vital few” critical issues through root cause analysis techniques. Not all problems require equal attention – by focusing on the most significant issues, you’ll maximize the impact of your improvement efforts.

Your measurement activities should align with the objectives established during the Define phase. This ensures you’re collecting data directly relevant to your project success criteria rather than getting distracted by interesting but irrelevant metrics.

Remember that DMAIC in quality improvement is iterative. The information gathered during the Measure phase often prompts refinements to your project scope and objectives. This flexibility allows you to adapt as you gain deeper insights into your process.

Without data, you’re just another person with an opinion.

hbr.org

Analyze Phase: Uncovering Root Causes

The Analyze phase is where your DMAIC in quality improvement journey gains momentum. This critical stage transforms data into actionable insights by identifying the root causes of problems rather than just treating symptoms. You’ll use statistical tools and structured techniques to pinpoint exactly what’s causing process variations and defects.

Essential Root Cause Analysis Techniques

When implementing DMAIC in quality processes, you’ll rely on several powerful analytical methods:

- Fishbone (Ishikawa) Diagrams: Create visual representations that connect potential causes to the problem, organizing them into categories like people, methods, machines, materials, measurements, and environment.

- 5 Whys Analysis: Drill down to underlying causes by repeatedly asking “why” to move beyond surface issues in your DMAIC in quality project.

- Pareto Analysis: Identify the vital few issues causing the majority of problems using the 80/20 principle, helping you prioritize which areas of DMAIC in quality to focus on first.

- Statistical Hypothesis Testing: Validate or reject theories about process performance using t-tests, ANOVA, chi-square, and regression analysis.

- Process Value Analysis: Evaluate which steps add value and which create waste or variation in your DMAIC in quality improvement effort.

Advanced statistical tools play a crucial role in this phase. You can conduct a root cause analysis using correlation studies to identify relationships between variables. Additionally, multi-vari analysis helps you examine how different factors interact to affect process outcomes.

The true power of the Analyze phase lies in its ability to transform assumptions into facts. When properly executing DMAIC in quality initiatives, you’ll distinguish between correlation and causation through rigorous data analysis. This prevents you from implementing solutions that don’t address the real issues.

Remember to engage cross-functional teams during this phase. Their diverse perspectives often uncover root causes that might otherwise remain hidden. Consider organizing structured brainstorming sessions where continuous improvement ideas can be shared and evaluated against the data you’ve collected.

By thoroughly analyzing root causes, you’ll establish a solid foundation for the subsequent Improve phase of your DMAIC in quality project, ensuring that your solutions directly address the most significant factors affecting process performance.

Improve Phase: Developing and Implementing Solutions

The Improve phase is where your DMAIC in quality process transitions from analysis to action. After identifying root causes in the Analyze phase, you’ll now focus on creating, testing, and implementing effective solutions to fix problems at their source.

During this critical stage, you’ll generate multiple potential improvements through structured techniques. Brainstorming sessions encourage creative thinking, allowing your team to develop innovative solutions that address root causes identified earlier. Design of Experiments (DOE) provides a systematic approach to test different variables and determine optimal process settings.

Before full-scale implementation, pilot testing is essential to validate that your proposed solutions work as intended. This methodical approach reduces risks associated with process changes while ensuring DMAIC in quality principles are maintained throughout. Your team should:

- Develop multiple potential solutions based on root cause analysis

- Evaluate each option based on feasibility, cost, and impact

- Create detailed implementation plans with clear responsibilities

- Test solutions in controlled environments before scaling

- Measure results against baseline data from earlier phases

The improve phase requires balancing technical improvements with stakeholder satisfaction. For maximum effectiveness, solutions should address both defect reduction and efficiency gains. According to DMAIC methodology, successful improvements often come from combinations of process redesign, technological upgrades, and procedural changes.

Implementation Best Practices

Successful implementation depends on more than just technical solutions—it requires careful planning and stakeholder management. When implementing DMAIC in quality improvements, you should:

- Create detailed transition plans to minimize disruption

- Develop training materials for all affected personnel

- Establish clear metrics to track implementation progress

- Communicate changes proactively to manage resistance

- Document all process modifications for future reference

Effective project communication becomes particularly important during implementation. Regular updates to stakeholders help maintain momentum and ensure continued support for your DMAIC in quality initiative. Remember that even the best technical solution can fail without proper change management.

The improve phase demonstrates how DMAIC in quality methodologies create tangible business value. By systematically developing and implementing data-driven solutions, you can achieve significant improvements in process performance, customer satisfaction, and overall operational efficiency. This structured approach ensures your improvement efforts deliver measurable results that align with organizational objectives.

Control Phase: Maintaining and Sustaining Improvements

The final stage in the DMAIC in quality methodology focuses on embedding improvements permanently into your operations. This crucial phase ensures your hard-won gains don’t slip away once the project spotlight moves elsewhere.

To maintain your process improvements, you’ll need to implement robust control mechanisms. These tools help you monitor performance and quickly address any deviations before they become significant problems. Statistical Process Control (SPC) charts serve as an early warning system, allowing you to monitor continuous improvement efforts effectively.

Essential Control Phase Activities

Your control phase should include several key components to sustain DMAIC in quality improvements:

- Documentation updates that capture new standard operating procedures

- Implementation of visual management systems to make process status immediately visible

- Development of response plans for when processes drift outside acceptable parameters

- Training programs to ensure all team members understand new procedures

- Regular audits to verify continued compliance with established standards

The control phase also requires establishing ownership. By clearly defining who’s responsible for ongoing monitoring, you’ll prevent the “nobody’s job” syndrome that often leads to regression. This post-implementation review process should identify the metrics that matter most.

Creating a comprehensive control plan is essential. This document outlines what you’ll measure, how frequently you’ll check it, acceptable performance ranges, and response protocols when issues arise. Your plan should include both process measures (how well the process is operating) and outcome measures (results the process delivers).

Technology plays a vital role in modern control mechanisms. Automated monitoring systems can continuously track performance, triggering alerts when metrics fall outside acceptable ranges. These systems remove human error from the monitoring process and ensure consistent vigilance over your DMAIC in quality improvements.

Remember that sustaining improvements requires cultural reinforcement. Recognition programs that celebrate teams maintaining enhanced performance levels help embed the DMAIC in quality mindset throughout your organization. By connecting improved processes to business outcomes, you’ll demonstrate the value of maintaining these new standards.