The PDCA Cycle in Total Quality Management

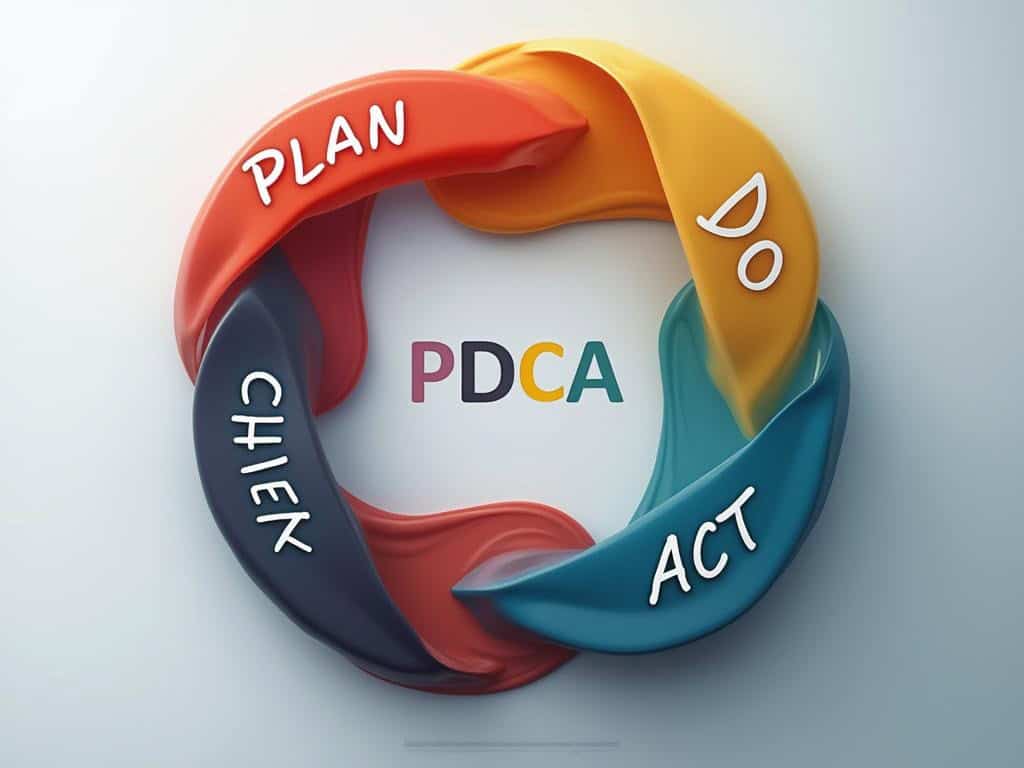

The PDCA cycle in total quality management offers a systematic framework that drives continuous improvement across organizational processes. Developed by W. Edwards Deming, this iterative approach transforms quality management by establishing a structured, scientific method for solving problems and improving organizational performance.

Key Takeaways:

- The PDCA cycle is an iterative four-stage framework for systematic problem-solving and continuous improvement.

- Developed by W. Edwards Deming, the cycle promotes data-driven decision-making in quality management.

- Each stage (Plan, Do, Check, Act) builds upon the previous one to create a virtuous improvement loop.

- The methodology can be applied across various industries to enhance operational efficiency.

- Successful implementation requires clear objectives, controlled testing, and rigorous performance evaluation.

This quality management approach, also known as the Deming Cycle, has revolutionized how organizations address process inefficiencies. You’ll find the PDCA methodology particularly valuable when tackling complex operational challenges that require structured analysis. Modern businesses increasingly rely on this framework to create a culture of continuous improvement that yields tangible results.

The beauty of PDCA lies in its adaptability. From manufacturing to healthcare and software development, organizations implement this cycle to optimize their processes. By following each step methodically, you can identify root causes of problems and develop effective solutions based on actual data rather than assumptions. This scientific approach to quality management delivers consistent, measurable improvement results that contribute directly to operational excellence.

“The PDCA cycle, a transformative framework developed by W. Edwards Deming, empowers organizations to embrace continuous improvement through an iterative approach to problem-solving. By fostering data-driven decision-making, this methodology cultivates a culture of efficiency and excellence across diverse industries.”

Origins and Conceptual Foundation

The PDCA cycle in total quality management provides a systematic framework for driving continuous improvement. Developed by quality management pioneer W. Edwards Deming, this iterative approach has become central to modern quality systems. The cycle embodies scientific method principles, offering a structured way to solve problems and enhance organizational performance.

Deming’s vision for the PDCA cycle in total quality management centered on creating a culture of ongoing improvement rather than sporadic fixes. This approach transforms how organizations address quality issues by establishing a repeatable methodology for enhancement. The PDCA cycle in total quality management represents a cornerstone of continuous improvement practices across industries.

The fundamental purpose of the PDCA cycle in total quality management is to drive systematic improvement in business processes and operations. By following this structured approach, you’ll create a foundation for data-driven decision-making that elevates quality standards. The cycle ensures that improvements aren’t left to chance but are methodically planned, implemented, evaluated, and standardized.

Key Components of Deming’s Framework

The PDCA cycle in total quality management consists of four interconnected stages that form a virtuous loop of improvement. Here’s how each component contributes to the overall framework:

- Plan: Identify problems or opportunities through root cause analysis and establish measurable objectives

- Do: Implement solutions on a small scale to minimize risk while collecting performance data

- Check: Evaluate results against original targets using statistical methods and performance indicators

- Act: Standardize successful changes and prepare for the next improvement cycle

This structured approach ensures that the PDCA cycle in total quality management delivers consistent results. By applying these principles, you’ll establish a process improvement system that continuously enhances quality. The cycle’s iterative nature means that improvement becomes an ongoing journey rather than a one-time destination.

The table below highlights how the PDCA cycle differs from traditional improvement approaches:

| PDCA Approach | Traditional Approach |

|---|---|

| Systematic and structured | Ad-hoc and reactive |

| Data-driven decisions | Intuition-based decisions |

| Continuous learning | One-time fixes |

| Root cause focused | Symptom focused |

| Process standardization | Inconsistent solutions |

When implementing the PDCA cycle in total quality management, you’ll find that it seamlessly integrates with other methodologies like Lean and Six Sigma. This compatibility makes it an essential component of comprehensive quality management systems that drive organizational excellence. The cycle’s emphasis on data and continuous learning creates a foundation for sustainable improvement in today’s competitive business environment.

Organizations that implement the PDCA cycle demonstrate a 50% increase in their ability to improve quality standards and drive performance efficiency, highlighting the importance of a structured approach to continuous improvement.

hbr.org

The Four Stages of the PDCA Cycle

The PDCA cycle in total quality management provides a structured approach for continuous improvement in organizational processes. Developed by W. Edwards Deming, this iterative framework helps you systematically address problems and implement effective solutions through four distinct stages.

Plan: Strategic Problem Identification

The PDCA cycle in total quality management begins with comprehensive planning. You’ll need to thoroughly analyze the problem through root cause investigation and establish a clear performance baseline using data collection techniques. This stage requires you to:

- Identify specific issues requiring improvement

- Collect relevant data to understand the current situation

- Establish measurable objectives for the improvement process

- Develop detailed action plans with clear timelines and responsibilities

- Create solution hypotheses based on your analysis

When you define project success criteria, you’re establishing the foundation for measuring outcomes during later PDCA stages. The planning phase accounts for approximately 40% of your total improvement effort but determines 80% of your results.

Do: Implementation of Solutions

The Do phase involves implementing your planned solutions in a controlled environment. You’ll want to:

- Execute small-scale pilots to test proposed solutions

- Minimize organizational risk through limited implementation

- Document all actions and collect performance data

- Train team members on new procedures

- Address unexpected challenges as they arise

Check: Evaluation of Results

During the Check stage, you’ll rigorously evaluate the results against your original objectives. This crucial step in the PDCA cycle in total quality management involves:

- Analyzing collected data using statistical methods

- Comparing actual outcomes with predicted results

- Identifying any variances or unexpected outcomes

- Evaluating the effectiveness of the implemented solution

- Documenting lessons learned during implementation

Continuous improvement principles are reinforced in the Act stage, where you’ll standardize successful changes or restart the cycle as needed. Your actions will include:

- Implementing successful solutions across the organization

- Updating standard operating procedures to reflect improvements

- Sharing knowledge and lessons learned with relevant stakeholders

- Identifying opportunities for further refinement

- Planning the next PDCA cycle if results don’t meet expectations

Summary of PDCA Stages

The following table summarizes key activities and outputs for each stage of the PDCA cycle in total quality management:

| PDCA Stage | Key Activities | Primary Outputs |

|---|---|---|

| Plan | Problem analysis, goal setting, action planning | Improvement objectives, action plans, performance metrics |

| Do | Pilot implementation, data collection, process execution | Implementation records, initial performance data |

| Check | Data analysis, performance evaluation, variance identification | Performance reports, gap analysis, improvement opportunities |

| Act | Standardization, procedure updates, knowledge sharing | Updated processes, lessons learned documentation, next-cycle planning |

The PDCA cycle in total quality management drives organizational learning through systematic problem-solving. By applying this framework, you can achieve measurable improvements while building a culture of continuous enhancement throughout your organization.

Plan: Strategic Problem Identification

The PDCA cycle in total quality management begins with thorough planning. This critical first phase sets the foundation for successful improvement initiatives. You’ll need to invest time in identifying problems accurately before jumping to solutions.

Start by conducting comprehensive root cause analysis to understand the true nature of issues affecting quality. The PDCA cycle in total quality management requires you to gather relevant data to establish performance baselines. This data-driven approach enables you to conduct a root cause analysis that reveals underlying issues rather than just addressing symptoms.

When implementing the PDCA cycle in total quality management, develop clear, measurable objectives for your improvement initiatives. Your goals should follow SMART criteria (Specific, Measurable, Achievable, Relevant, Time-bound) to provide direction and accountability throughout the process.

Key Planning Activities

The planning phase encompasses several crucial activities that support the PDCA cycle in total quality management:

- Problem definition and scoping to clearly articulate what needs improvement

- Data collection methods selection to ensure accurate information gathering

- Root cause analysis techniques like 5-Why, fishbone diagrams, or Pareto analysis

- Solution hypothesis development based on evidence and team input

- Resource allocation planning to support implementation efforts

- Timeline development with specific milestones and checkpoints

Your success with the PDCA cycle in total quality management depends on this planning foundation. Without proper problem identification, you risk wasting resources on ineffective solutions. The planning phase creates continuous improvement opportunities by ensuring teams understand both the problem and potential approaches to resolution.

Remember that the PDCA cycle in total quality management is iterative. Your planning efforts will be refined through subsequent cycles as you learn more about your processes and the effectiveness of your solutions. This systematic approach, pioneered by W. Edwards Deming, provides a structured framework for tackling complex quality challenges in any industry.

Do: Controlled Implementation

The “Do” phase is where your theoretical plans come to life in the PDCA cycle in total quality management. Instead of making sweeping changes across your organization, this stage advocates for controlled implementation through pilot testing or small-scale trials. You’ll reduce potential risks by testing solutions in limited environments before full-scale deployment.

During this critical phase of the PDCA cycle in total quality management, your team executes the planned solutions while simultaneously collecting performance data. This data collection is essential for the upcoming “Check” phase and helps you understand how your implemented changes are performing in real-world conditions.

Key Elements of Effective Implementation

When implementing changes in the PDCA cycle in total quality management, focus on these essential components:

- Clear communication to all stakeholders about the changes being implemented

- Proper training for team members involved in the new process

- Detailed documentation of the implementation steps and procedures

- Consistent data collection methods to track progress

- Regular check-ins with the implementation team to address immediate concerns

The controlled approach of the “Do” phase lets you implement risk response strategies that protect your core operations. By limiting the scope of implementation, you can quickly identify and address issues before they affect your entire organization.

| Traditional Implementation | PDCA “Do” Phase Implementation |

|---|---|

| Full-scale rollout | Controlled pilot testing |

| Limited data collection | Systematic performance monitoring |

| Often irreversible | Adaptable based on results |

| Higher organizational risk | Minimized risk exposure |

| Less opportunity for adjustment | Continuous refinement opportunity |

The “Do” phase of the PDCA cycle in total quality management creates a safe environment for testing hypotheses developed during the “Plan” stage. Your organization can gather crucial implementation insights while minimizing disruption to existing operations. This approach aligns with continuous improvement principles by allowing for iterative refinement before committing resources to full-scale implementation.

Remember that documentation during this phase is crucial – you’re not just implementing solutions but creating a knowledge base that will inform future improvement cycles in your PDCA cycle in total quality management efforts.

Organizations that successfully implement controlled changes experience a 30% reduction in project failures compared to those that opt for full-scale rollouts without pilot testing.

hbr.org

Check: Rigorous Performance Evaluation

The Check phase represents a critical juncture in the PDCA cycle in total quality management where you’ll evaluate whether your implemented solutions have achieved their intended outcomes. This analytical stage transforms raw data into actionable insights that drive continuous improvement efforts forward.

During this evaluation phase, you’ll need to conduct a comparative analysis of your implemented changes against your original objectives. The PDCA cycle in total quality management relies on evidence-based assessment rather than assumptions. You’ll analyze performance metrics, collect feedback, and measure results using statistical methods like hypothesis testing, regression analysis, and control charts to determine the effectiveness of your solutions.

The Check phase helps you identify variances between expected and actual outcomes. By examining these discrepancies through the lens of the PDCA cycle in total quality management, you’ll uncover valuable learning opportunities. Your findings might reveal unexpected consequences, additional improvement areas, or confirm your hypothesis was correct.

Key Evaluation Techniques

When performing evaluations within the PDCA cycle in total quality management framework, consider implementing these assessment methods:

- Statistical Process Control (SPC) charts to monitor process stability

- Comparative before-and-after data analysis to quantify improvements

- Customer feedback analysis to gauge satisfaction changes

- Performance indicator tracking to measure progress toward objectives

- Variance analysis to identify deviations from expected outcomes

The Check phase connects directly to both previous and subsequent PDCA stages. Your evaluation findings inform whether you should continue your improvement efforts in the Act phase or return to the Plan phase to revise your approach. This systematic assessment helps you avoid making permanent changes that don’t deliver results, making the PDCA cycle in total quality management a risk-mitigating framework.

Remember that this evaluation isn’t simply a checkbox exercise but a thoughtful examination of what worked, what didn’t, and why. Your success criteria should be clearly defined during the Plan phase to facilitate objective assessment during Check. The rigor you apply during this evaluation directly impacts the quality of decisions you’ll make in subsequent improvement cycles.

Act: Standardization and Continuous Improvement

The Act phase is the crucial final step in the PDCA cycle in total quality management where you transform successful improvements into standard practice. After confirming that your implemented solutions have achieved the desired results, you’ll need to standardize these changes across your organization to ensure consistency and sustainability.

Standardization involves updating your existing standard operating procedures (SOPs) to incorporate the newly validated improvements. This documentation ensures the PDCA cycle in total quality management creates lasting change rather than temporary fixes. You should provide thorough training to all affected team members on these updated procedures to maintain compliance and effectiveness.

When implementing the PDCA cycle in total quality management, it’s essential to create mechanisms for knowledge sharing. The insights gained during the improvement process should be shared across departments through:

- Documented case studies highlighting key learnings

- Cross-functional team meetings to discuss successful implementations

- Updated training materials incorporating new best practices

- Accessible knowledge repositories for future reference

Preparing for the Next Improvement Cycle

If your results fell short of objectives, the PDCA cycle in total quality management allows you to start again with refined approaches. You’ll need to conduct a thorough root cause analysis to determine why the implemented solution didn’t deliver expected outcomes.

The Act phase isn’t merely about implementing successful changes—it’s about creating a foundation for ongoing improvement. By establishing continuous improvement as a core organizational value, you build a culture where the PDCA cycle in total quality management becomes second nature.

For maximum benefit, integrate your standardized improvements with broader quality management systems. This integration ensures the PDCA cycle in total quality management enhances organizational adaptability while reducing variability in processes. You’ll find this particularly valuable when facing unexpected project roadblocks that require systematic problem-solving approaches.

The true power of the PDCA cycle in total quality management emerges when it becomes embedded in your organizational DNA—creating a self-reinforcing cycle of improvement that drives both efficiency and quality forward simultaneously.

Strategic Applications in Total Quality Management

The PDCA cycle in total quality management serves as a fundamental framework for organizations seeking systematic improvement. Developed by W. Edwards Deming, this iterative approach transforms how you implement quality initiatives across your business operations. The PDCA cycle in total quality management helps you establish a methodical path to excellence through its four distinct phases.

You’ll find the PDCA cycle in total quality management particularly valuable when integrating quality practices across various departments. This structured approach allows for continuous improvement while maintaining operational stability. The cycle’s adaptability makes it applicable in manufacturing, healthcare, technology, and service industries alike.

Integration with Modern Quality Methodologies

The PDCA cycle in total quality management aligns seamlessly with other quality frameworks. You can enhance your existing processes by combining the PDCA cycle in total quality management with Lean principles and Six Sigma methodologies. This integration creates a powerful system for eliminating waste while maximizing efficiency.

- The Plan phase requires you to analyze problems through root cause investigation and establish clear performance baselines.

- During the Do phase, you’ll implement solutions in controlled environments to minimize organizational risk.

- The Check phase involves evaluating results against objectives using statistical methods.

- In the Act phase, you’ll standardize successful solutions and prepare for the next improvement cycle.

The PDCA cycle in total quality management promotes a data-driven decision-making culture throughout your organization. By consistently applying this framework, you’ll create an environment where quality isn’t just monitored but actively improved. This systematic approach helps your teams address quality issues before they affect customer satisfaction.

Using the PDCA cycle in total quality management can significantly enhance your project success criteria. The framework provides structure for defining measurable objectives, implementing changes carefully, and evaluating outcomes objectively. Each cycle builds upon previous learnings, creating a continuous path toward operational excellence.

The following table illustrates key benefits of implementing the PDCA cycle in total quality management:

| Benefit | Description |

|---|---|

| Risk Mitigation | Controlled changes reduce implementation risks. |

| Enhanced Learning | Systematic evaluation creates organizational knowledge. |

| Process Standardization | Successful improvements become standard practices. |

| Competitive Advantage | Continuous quality improvement strengthens market position. |

| Employee Engagement | Structured approach encourages participation at all levels. |

When properly implemented, the PDCA cycle in total quality management transforms how your organization addresses challenges and pursues opportunities for improvement. Its scientific approach to problem-solving ensures that quality initiatives aren’t based on assumptions but on verifiable data and systematic testing.

Practical Implementation and Organizational Benefits

Implementing the PDCA cycle in total quality management creates a systematic framework for your organization’s continuous improvement efforts. The PDCA cycle in total quality management provides a structured approach that transforms abstract quality concepts into actionable steps. You’ll find this methodology particularly valuable when facing complex operational challenges that require methodical solutions.

To successfully implement the PDCA cycle in your organization, you’ll need to focus on several key areas. First, establish clear ownership of each phase, ensuring accountability throughout the process. Your team should collaborate effectively on projects by maintaining transparent communication channels. When implementing the PDCA cycle in total quality management, documentation becomes essential for tracking progress and capturing learnings.

The PDCA cycle offers numerous organizational benefits that extend beyond individual process improvements. Here’s how your organization can benefit from implementing this framework:

- Enhanced problem-solving capabilities through structured analysis

- Improved resource allocation by targeting high-impact improvement areas

- Reduced implementation risks through controlled pilot testing

- Strengthened data-driven decision-making culture

- Increased employee engagement through participation in improvement initiatives

Measuring PDCA Success

Tracking specific metrics helps you evaluate the effectiveness of your PDCA cycle implementation. The PDCA cycle in total quality management requires establishing baseline measurements before changes are introduced. This allows you to accurately assess improvement impacts. You’ll want to develop a strategic dashboard that tracks key performance indicators across each PDCA phase.

The following table outlines common metrics used to measure success across the PDCA cycle phases:

| PDCA Phase | Key Metrics | Purpose |

|---|---|---|

| Plan | Problem definition clarity, root cause identification rate | Ensures proper problem framing |

| Do | Implementation adherence, resource utilization | Tracks execution effectiveness |

| Check | Variance from targets, statistical significance | Validates improvement impact |

| Act | Standard adoption rate, knowledge transfer completion | Measures institutionalization |

The PDCA cycle in total quality management creates a foundation for sustainable improvement. By establishing this methodology within your quality management system, you’ll develop an organizational capability for adaptive problem-solving. Your teams will gradually adopt the PDCA mindset, applying its principles to challenges across departments. This systematic approach ultimately transforms how your organization handles quality challenges, replacing reactive firefighting with proactive improvement.