Introduction to Lean Six Sigma

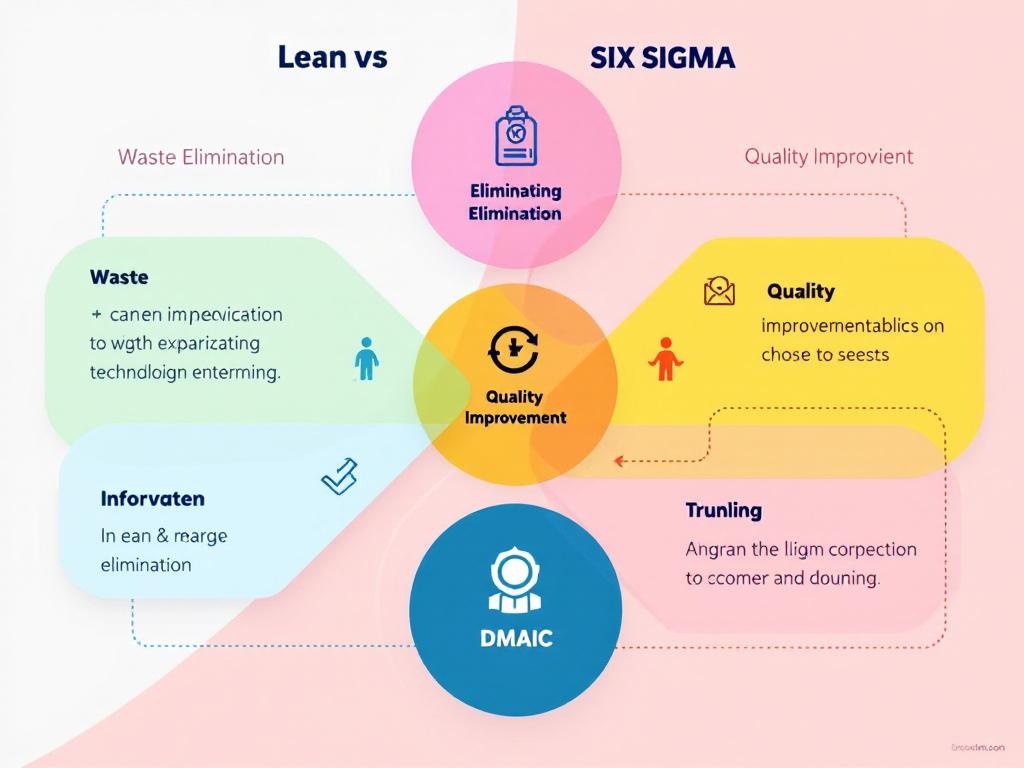

Lean Six Sigma is a powerful methodology that combines Lean’s waste elimination principles with Six Sigma’s data-driven quality improvement approach. This integrated system creates a complete framework for enhancing operational excellence across organizations. By providing a structured approach to identifying and solving process problems, it focuses on reducing waste, improving efficiency, and achieving near-perfect quality through continuous improvement.

Key Takeaways

- Lean Six Sigma merges Lean principles of waste elimination with Six Sigma’s statistical quality control techniques

- The methodology aims to achieve 3.4 defects per million opportunities, representing 99.99966% accuracy

- It provides a structured DMAIC framework (Define, Measure, Analyze, Improve, Control) for problem-solving

- The approach works across multiple industries, including manufacturing, healthcare, finance, and services

- Implementation can lead to significant benefits such as reduced cycle times, decreased costs, and increased customer satisfaction

Benefits of Lean Six Sigma

The combination of these two methodologies delivers exceptional results for organizations committed to process excellence. Lean methodology focuses on eliminating waste, while Six Sigma targets variation reduction. Together, they form a comprehensive strategy that addresses both efficiency and quality challenges.

Your organization can benefit from implementing this methodology regardless of industry type or size. Healthcare facilities use it to reduce patient wait times and improve care quality. Manufacturing companies apply these principles to streamline production lines and decrease defects. Even service-based businesses utilize Lean Six Sigma to optimize customer experience and back-office operations.

The DMAIC Process

The DMAIC process serves as the backbone of Lean Six Sigma projects. Each phase builds logically on the previous one, creating a clear path from problem identification to sustainable solution. This structured approach helps teams stay focused on data-driven decisions rather than opinions or assumptions.

Impact of Implementation

Companies that successfully implement Lean Six Sigma often report dramatic improvements in their operations. Cost savings typically range from 20-50% in targeted process areas. Cycle times frequently decrease by 30-60%, allowing faster response to customer needs. Additionally, your staff becomes more engaged as they gain skills to solve problems systematically rather than applying temporary fixes to recurring issues.

Learning and Certification

Learning Six Sigma certification requires dedication but offers substantial personal and organizational benefits. The belt system (White, Yellow, Green, Black, Master Black) provides clear progression paths for practitioners at all levels of expertise.

“Lean Six Sigma transcends traditional operational strategies by seamlessly blending waste reduction with data-driven quality enhancement, forging a path toward unparalleled excellence. Its robust DMAIC framework empowers organizations across various industries to not only tackle process challenges but to thrive through continuous improvement and near-perfect quality.”

Understanding Lean Six Sigma: A Comprehensive Process Improvement Methodology

Lean Six Sigma combines two powerful methodologies to create an unbeatable approach to process improvement. At its core, what is Lean Six Sigma? It’s a comprehensive methodology that merges Lean principles (focused on eliminating waste and optimizing workflow) with Six Sigma’s data-driven approach to quality improvement and variation reduction. This combination delivers remarkable results for organizations seeking operational excellence.

The methodology evolved from Toyota’s Production System (the Lean component) and Motorola’s Six Sigma program developed in the 1980s. While Lean targets efficiency and flow, Six Sigma aims for near-perfect quality with a goal of achieving just 3.4 defects per million opportunities – that’s 99.99966% accuracy!

Core Principles Driving Lean Six Sigma Success

Several fundamental principles make Lean Six Sigma effective across various industries:

- Customer Focus – You’ll prioritize understanding and meeting customer needs in every process

- Value Stream Identification – You can visualize entire processes to identify waste and inefficiencies

- Flow Creation – You’ll establish smooth, uninterrupted process sequences

- Pull System Establishment – You’ll align production to actual demand, preventing overproduction

- Pursuit of Perfection – You’ll maintain a continuous improvement mindset

The DMAIC framework provides the structured backbone for root cause analysis and problem-solving:

- Define – Set project goals, create problem statements, develop project charters

- Measure – Collect baseline data to understand current performance

- Analyze – Identify root causes using tools like Fishbone diagrams and Pareto charts

- Improve – Develop, test, and implement solutions

- Control – Standardize improvements and establish control plans

This methodology cultivates organization-wide commitment to improvement and helps you identify the eight types of waste (muda). The process improvement techniques work across manufacturing, healthcare, finance, and service industries, making Lean Six Sigma a versatile approach to excellence.

When properly implemented, you’ll see dramatic reductions in defects, shorter cycle times, decreased costs, increased customer satisfaction, and a culture that embraces continuous improvement. The methodology’s power lies in combining Lean’s speed and efficiency with Six Sigma’s precision and quality control.

Organizations that implement Lean Six Sigma can achieve up to a 40% reduction in process cycle times, leading to significant financial savings and improved customer satisfaction.

forbes.com

Core Principles Driving Lean Six Sigma Success

What is Lean Six Sigma? It’s a powerful methodology that combines Lean’s waste elimination focus with Six Sigma’s data-driven quality improvement approach. This integrated methodology creates a comprehensive system for enhancing operational excellence across organizations of all sizes.

The foundation of Lean Six Sigma rests on several core principles that drive its effectiveness. These principles work together to create sustainable process improvements while maintaining a relentless focus on what matters most – customer satisfaction.

Customer-Centric Value Creation

You’ll find that successful Lean Six Sigma implementations always begin with understanding customer requirements. This customer-centric approach ensures that all improvement efforts align with what truly matters to those you serve. When you clearly define value from the customer’s perspective, you can more effectively:

- Identify activities that directly contribute to customer satisfaction

- Eliminate steps that don’t add value to the end product or service

- Prioritize improvement initiatives based on customer impact

- Establish meaningful metrics that reflect customer priorities

- Create feedback loops to continually refine customer understanding

Value stream mapping helps you visualize your entire process flow to spot inefficiencies and bottlenecks that impact customer value. This value stream analysis tool reveals where waste occurs and where flow gets interrupted.

The pursuit of perfection through continuous improvement forms another cornerstone of what is Lean Six Sigma. This isn’t about achieving absolute perfection but establishing a mindset where teams constantly seek better ways to work. This involves:

- Creating pull systems that respond to actual demand rather than forecasts

- Establishing flow by removing interruptions and waiting periods

- Eliminating the eight forms of waste (Muda) from all processes

- Implementing standard work practices to reduce variation

- Empowering teams to identify and solve problems at their source

The cultural transformation required for Lean Six Sigma success can’t be overlooked. When you build a culture of improvement, everyone becomes responsible for continuous improvement and problem-solving rather than just designated specialists.

The statistical rigor of Six Sigma complements Lean’s flow focus, targeting the reduction of defects to 3.4 per million opportunities. This exacting standard drives teams to use data for decision-making rather than assumptions or gut feelings.

The DMAIC Framework: Structured Problem-Solving Methodology

The DMAIC framework forms the backbone of what is lean six sigma, providing a structured approach to identifying and solving process problems. This five-phase methodology transforms how you address organizational challenges through systematic analysis and improvement.

Breaking Down DMAIC Phases

The Define phase establishes the foundation of your improvement project. You’ll create clear project charters that outline specific goals, problem statements, and project scope. This initial step helps you identify key stakeholders and establish metrics for success, ensuring everyone understands what is lean six sigma trying to accomplish in your specific context.

During the Measure phase, you’ll collect baseline data to understand current performance levels. Process mapping techniques help visualize workflows while measurement systems analysis validates your data collection methods. This phase is crucial as it provides the quantitative foundation for all subsequent improvement efforts.

The Analyze phase digs deeper into identifying root causes of problems. You’ll employ analytical tools like Fishbone diagrams to explore cause-effect relationships, conduct 5 Whys analysis to uncover underlying issues, and use Pareto charts to identify the vital few causes responsible for most problems. Proper root cause analysis prevents you from addressing symptoms rather than true problems.

In the Improve phase, you’ll develop, test and implement solutions based on your analysis. This involves generating creative solutions, piloting improvements, and monitoring results continuously. Many organizations implement process optimization services to support this critical stage, ensuring changes deliver expected benefits.

Finally, the Control phase ensures improvements stick. You’ll standardize new processes, establish control plans with key performance indicators, train employees on new methods, and conduct regular audits. This systematic approach to what is lean six sigma implementation creates a sustainable culture of improvement.

The power of DMAIC lies in its structured, data-driven approach. By following this methodology, you’ll avoid common pitfalls like jumping to solutions before understanding problems or implementing changes without proper validation. Instead, you’ll develop evidence-based improvements that deliver measurable results while building organizational capability in continuous improvement.

This framework doesn’t operate in isolation—it works best when integrated with other aspects of what is lean six sigma, including waste elimination principles and statistical quality control. The combination ensures you address both process efficiency and quality simultaneously, maximizing your improvement impact.

Organizations that embrace DMAIC methodology see an average of 30-50% reduction in process cycle times, leading to enhanced efficiency and customer satisfaction.

hbr.org

Essential Tools and Techniques for Implementation

Successfully implementing what is lean six sigma requires mastering a specific set of powerful tools. You’ll need both analytical and visual techniques to identify problems, analyze data, and drive process improvement.

Lean Six Sigma Toolkit Essentials

Lean tools help you visualize workflow and eliminate waste in your processes:

- Value Stream Mapping (VSM) – Creates visual representations of your information and material flows, highlighting bottlenecks and non-value-adding activities

- 5S Methodology – Organizes workspaces through Sort, Set in order, Shine, Standardize, and Sustain practices

- Kanban Boards – Visualizes work in progress to control flow and identify constraints

- Poka-Yoke – Implements error-proofing devices to prevent defects at their source

- Quick Changeover (SMED) – Reduces setup times between process changes

Six Sigma’s analytical tools provide the statistical rigor needed for data-driven decisions:

- Statistical Process Control (SPC) Charts – Monitors process variation in real-time

- Regression Analysis – Identifies relationships between variables affecting outcomes

- Design of Experiments (DOE) – Tests multiple factors simultaneously to optimize processes

- Failure Mode and Effects Analysis (FMEA) – Prioritizes potential failure points based on severity, occurrence, and detection

- Hypothesis Testing – Validates whether observed differences are statistically significant

When implementing what is lean six sigma, you’ll need to select the right tools for each DMAIC project phase. For example, during the Define phase, you might use a project charter and SIPOC diagram to establish scope, while the Analyze phase would leverage fishbone diagrams and Pareto analysis to identify root causes.

Proper tool selection depends on your project’s complexity and the specific process improvement system challenges you face. Remember that successful implementation requires more than just technical proficiency – it demands a cultural shift toward continuous improvement and data-driven decision making.