Business Process Management Lean

Business process management lean combines two powerful methodologies to drive operational excellence. This structured approach analyzes and improves business processes while eliminating waste. By integrating Business Process Management with Lean principles, you’ll create a comprehensive framework that addresses both process architecture and resource optimization.

Key Takeaways

- Business process management lean enables organizations to reduce costs by 20-30% while improving overall quality and customer satisfaction.

- The approach focuses on five core principles:

- Identifying value

- Mapping the value stream

- Creating flow

- Establishing pull systems

- Pursuing continuous improvement

- Value stream mapping is a critical tool that reveals non-value-added activities and helps decompose complex processes.

- Implementing this methodology requires categorizing activities as value-adding, necessary non-value-adding, or pure waste.

- The integration of BPM and Lean thinking transforms operational strategies by eliminating inefficiencies and optimizing workflows.

This integrated approach delivers significant benefits for organizations seeking to streamline operations. Companies implementing BPM lean techniques typically see dramatic efficiency gains through waste reduction and process optimization. The methodology helps identify bottlenecks that slow down production and delivery cycles.

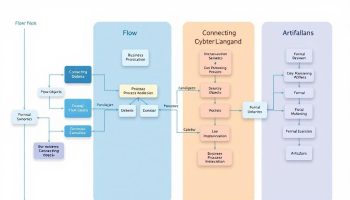

Value Stream Mapping

Value stream mapping stands out as an essential technique in this framework. This visual tool tracks the flow of materials and information needed to deliver products or services to customers. Through careful analysis, you can identify steps that add no value and develop strategies to eliminate them.

Implementation Strategies

Implementation requires a systematic categorization of all activities within your processes. Each task must be classified based on its contribution to customer value. The goal is to maximize value-adding activities while minimizing or eliminating those that don’t contribute to customer satisfaction.

The Fusion of Methodologies

The fusion of these methodologies creates a powerful system for operational transformation. By applying Lean BPM principles, you’ll build organizations that respond quickly to market changes while maintaining high quality standards and cost efficiency.

“By seamlessly merging Business Process Management with Lean principles, organizations can unlock unprecedented operational excellence, achieving cost reductions of 20-30% while simultaneously enhancing quality and customer satisfaction. This powerful integration not only streamlines workflows and eliminates inefficiencies but also fosters a culture of continuous improvement, ensuring value-driven processes that resonate with customers.”

The Integration of BPM and Lean: Creating a Framework for Operational Excellence

Business process management lean combines two powerful methodologies to drive operational excellence. BPM provides the structured backbone for analyzing, redesigning, modeling, implementing, and monitoring business processes, while Lean focuses on eliminating waste and delivering more value with fewer resources. When integrated properly, you’ll create a comprehensive framework that addresses both process architecture and waste reduction simultaneously.

You can achieve dramatic improvements in cost, quality, and time by implementing this integrated approach. BPM offers the end-to-end process view needed to understand how work flows through your organization, while Lean principles provide the practical tools to remove inefficiencies. This continuous improvement synergy creates sustainable operational excellence.

The Five Core Lean Principles in BPM Implementation

When applying Lean principles to your business process management efforts, focus on these five core elements:

- Identify Value – Define value strictly from the customer’s perspective, focusing on what they’re willing to pay for.

- Map the Value Stream – Document all steps, people, and handoffs to visualize the entire process.

- Create Flow – Remove bottlenecks and delays to ensure smooth, uninterrupted workflow.

- Establish Pull Systems – Implement demand-based workflows rather than forecast-driven production.

- Pursue Perfection – Commit to continuous business process management lean improvement.

Value stream mapping serves as a critical tool in process optimization methods by revealing non-value-added activities and lead time drivers. This technique helps decompose high-level processes into detailed steps where you can identify waste points. Typically, 70-80% of total lead time consists of waiting or idle time rather than value-adding activity.

| BPM Contribution | Lean Contribution |

|---|---|

| Process architecture | Waste identification |

| End-to-end visibility | Flow optimization |

| Process standardization | Pull systems |

| Governance structure | Continuous improvement |

| Technology enablement | Value focus |

When implementing business process management lean practices, you’ll need to categorize activities as value-adding, necessary non-value-adding, or pure waste. This classification helps prioritize improvement efforts and ensures you’re focusing on elements that deliver the most impact to customers and operational performance.

Companies that effectively integrate Lean and BPM can see improvements in productivity and quality by up to 30%.

forbes.com

The Five Core Lean Principles in BPM Implementation

Combining business process management with lean thinking transforms how you operate your business. This integration creates a powerful framework that eliminates waste while optimizing workflows. When properly implemented, the business process management lean approach can reduce costs by 20-30% while improving quality and customer satisfaction.

The foundation of this methodology rests on five core principles that guide implementation:

- Identify Value – Define value strictly from your customer’s perspective. This means understanding what they’re willing to pay for and eliminating everything else. When implementing continuous improvement, always start by asking: “Does this process step create value for the end customer?”

- Map the Value Stream – Document every step, person, and handoff involved in delivering your product or service. This comprehensive visualization exposes inefficiencies and creates opportunities for process optimization. Effective mapping requires cross-functional collaboration to ensure all perspectives are captured.

- Create Flow – Remove bottlenecks, delays, and interruptions to establish smooth workflows. This principle focuses on eliminating the starts and stops that plague most business processes. Your goal is to create a steady, predictable rhythm of work.

- Establish Pull Systems – Implement demand-based workflows rather than forecast-driven production. This prevents overproduction and reduces inventory costs. Pull systems respond to actual customer needs instead of pushing products based on predictions.

- Pursue Perfection – Commit to continuous improvement through regular evaluation and adaptation. This creates a culture where business process management lean thinking becomes ingrained in everyday operations.

Value Stream Mapping: The Critical Tool

Value stream mapping serves as the cornerstone of business process management lean integration. This powerful visualization technique reveals:

| Element | Function | Impact |

|---|---|---|

| Non-value activities | Identifies tasks that don’t contribute to customer value | Typically eliminates 40-60% of process steps |

| Lead time drivers | Pinpoints where delays occur | Reduces overall delivery time by 50-90% |

| Handoffs | Shows transfers between departments or people | Decreases errors by minimizing transitions |

| Bottlenecks | Highlights constraints limiting throughput | Improves capacity by addressing limitations |

When conducting value stream mapping, you’ll often discover that 70-80% of your total lead time involves waiting or idle time rather than value-adding activity. This insight allows you to focus process optimization methods on the areas that will deliver the greatest improvement.

The business process management lean approach requires categorizing all activities as value-adding, necessary non-value-adding, or pure waste. This classification enables strategic decisions about what to eliminate, what to reduce, and what to enhance.

Companies that implement lean principles can see improvements in productivity and efficiency by up to 80%.

hbr.org

Mapping the Value Stream: Exposing Waste and Creating Efficient Processes

Value stream mapping forms the backbone of business process management lean implementation, providing a visual representation of how work flows through your organization. This powerful technique exposes hidden waste and reveals opportunities for creating more efficient processes that deliver maximum value to customers.

When you integrate value stream mapping into your business process management approach, you’ll gain a complete picture of both material and information flows. This holistic view helps you identify where value is created and where it’s diminished through wasteful activities. Typically, 70-80% of total lead time in most processes consists of waiting or idle time rather than actual value-adding work.

The mapping process requires you to categorize each activity into one of three classifications:

- Value-adding activities: directly contribute to what customers will pay for

- Necessary non-value-adding activities: required but not valuable to customers

- Pure waste: activities that consume resources without adding value

Identifying the Eight Forms of Waste

To successfully implement business process management lean practices, you need to recognize the eight primary forms of waste that hamper operational excellence:

- Overproduction: Creating more than needed or before it’s needed

- Waiting: Idle time between process steps

- Transportation: Unnecessary movement of materials or information

- Overprocessing: Adding features customers don’t value

- Inventory: Excess materials or information waiting to be processed

- Motion: Unnecessary movement of people

- Defects: Errors requiring rework

- Underutilized talent: Failing to leverage employee skills and ideas

By applying process mapping techniques to document all steps, people, and handoffs, you’ll visualize bottlenecks that impede flow. This detailed analysis helps you decompose high-level processes into granular steps where you can identify critical failure points and opportunities for improvement.

Once you’ve exposed waste through value stream mapping, you can implement targeted continuous improvement initiatives to eliminate non-value-adding activities. Your goal should be creating smooth, uninterrupted workflow by removing delays and optimizing handoffs between process steps.

The business process management lean approach enables you to establish pull systems that respond to actual customer demand rather than relying on forecasts. This just-in-time delivery methodology minimizes inventory waste while ensuring customer needs are met promptly.

Value stream mapping can reduce lead times by 30-50% by identifying waste and streamlining processes.

hbr.org