VSM analysis offers a systematic approach to visualize, analyze, and improve the flow of materials and information needed to deliver products or services to customers. This methodology maps current process states, identifies inefficiencies, and helps create streamlined future states that maximize value creation.

Why Businesses Need VSM Analysis

VSM analysis functions as a key strategic tool for companies looking to boost operational efficiency and stay competitive. By offering a complete view of value flow throughout an organization, VSM analysis helps identify bottlenecks, cut waste, and decrease lead times—often improving efficiency by 20-50%. This method breaks down department barriers, enhancing cross-functional communication while providing measurable metrics for data-driven decisions.

For organizations watching their resources, VSM analysis optimizes staff and equipment allocation while aligning business processes with customer requirements, resulting in better product quality and quicker service delivery.

7 Key Benefits of VSM Analysis: Transform Your Operations for Greater Efficiency

Value Stream Mapping (VSM) analysis serves as a vital tool for organizations striving for operational excellence and enhanced value delivery. In this section, we’ll explore seven crucial benefits of implementing VSM analysis, each designed to streamline processes and foster significant improvements within your organization. From enhanced visibility into your workflows to data-driven decision-making, VSM provides the insights needed to eliminate waste, reduce lead times, and ultimately boost customer satisfaction. By focusing on these seven key aspects, you’ll gain a clearer understanding of how VSM can be leveraged for maximum impact, guiding your organization towards a more efficient and customer-centric approach. Dive into the details to discover how implementing these strategies can revolutionize your operations.

1. Enhanced Process Visibility

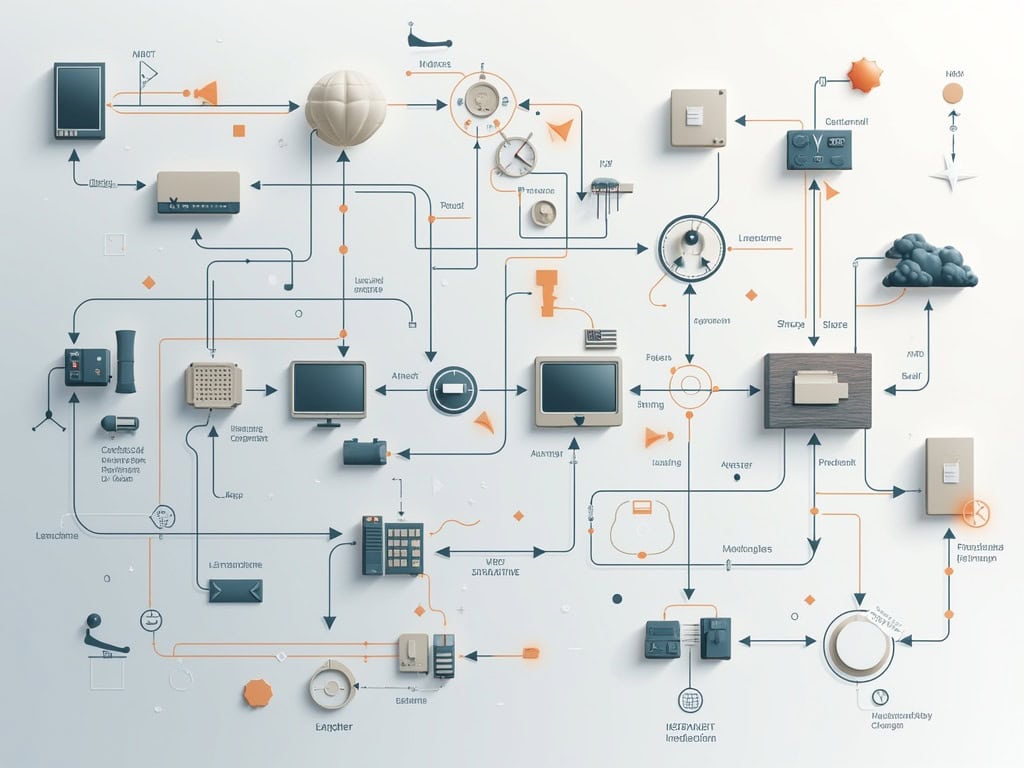

Implementing VSM analysis creates a clear visualization of your entire workflow. This powerful tool helps you see the complete picture of how value flows through your organization. When conducting a VSM analysis, you can identify hidden bottlenecks and inefficiencies that might otherwise remain concealed in complex operations. The mapping process reveals how materials, information, and activities connect, giving teams a comprehensive understanding of their role in the bigger picture.

With proper VSM analysis, you can track how each process contributes to your overall value delivery system. This visibility helps improve project collaboration by creating a shared visual language that crosses departmental boundaries. Teams can see upstream and downstream impacts of their work, fostering greater accountability and process ownership.

- Provides end-to-end visualization of information and material flow

- Highlights value-adding versus non-value-adding activities

- Creates a baseline for measuring improvement initiatives

- Enables easier identification of process constraints

2. Waste Elimination

Conducting a thorough VSM analysis helps businesses identify and eliminate non-value-adding activities throughout their operations. By mapping your process flows, you can spot redundant steps that consume resources without contributing to customer value. This systematic approach to waste identification becomes a powerful tool for cost reduction and efficiency improvement.

When implementing VSM analysis, you’ll categorize waste into specific types including overproduction, waiting time, unnecessary transportation, and excess inventory. This classification makes it easier to prioritize improvement efforts where they’ll have the greatest impact on your bottom line. Many organizations have achieved 20-30% cost reductions through targeted elimination of wasteful activities identified during VSM exercises.

Key benefits of waste elimination through VSM analysis include:

- Reduced operational costs through elimination of unnecessary steps

- Improved resource utilization across departments

- Enhanced process flow with fewer interruptions

- More sustainable operations with decreased material waste

The project scope baseline becomes clearer when waste is systematically removed, allowing you to focus on core value-creating activities. Your improvement initiatives become more effective when grounded in the detailed process understanding that VSM analysis provides.

Expert Insight: Conduct a thorough Value Stream Mapping (VSM) analysis to identify and eliminate non-value-adding activities. By categorizing waste, you can prioritize improvement efforts effectively, leading to significant cost reductions and enhanced efficiency. This systematic approach sharpens focus on core value-creating activities and improves overall operational sustainability.

3. Reduced Lead Times

Implementing VSM analysis significantly streamlines production cycles by identifying and eliminating delays in your workflow. The value stream mapping process reveals where time is wasted between operational steps, allowing you to minimize waiting periods that typically plague manufacturing and service delivery. By conducting thorough VSM analysis, your team can identify the exact points where work sits idle, creating unnecessary lag in the system.

This optimization directly accelerates time-to-market for your products and services, giving you a competitive edge in today’s fast-paced business environment. Companies that successfully apply VSM techniques often reduce their lead times by 20-50%, dramatically improving customer responsiveness. The project crashing techniques that emerge from VSM analysis can further compress timelines when needed for critical deliverables.

Consider these common lead time reductions achieved through VSM:

- Elimination of batch processing delays

- Reduction in approval wait times

- Minimized handoff delays between departments

- Decreased setup and changeover times

- Streamlined information flow alongside physical processes

Expert Insight: Implementing Value Stream Mapping (VSM) effectively identifies and eliminates delays in production, resulting in a 20-50% reduction in lead times. By optimizing workflow, businesses enhance responsiveness and accelerate time-to-market. Focus on minimizing batch processing, approval waits, and handoff delays to achieve significant efficiency gains.

4. Improved Cross-functional Communication

VSM analysis breaks down traditional departmental silos by creating a common visual language that all teams can understand. When conducting value stream mapping analysis, you establish a shared understanding of how processes flow across different functional areas. This visualization helps everyone see how their work impacts upstream and downstream activities.

By implementing VSM analysis in your organization, you enable better team collaboration as employees gain visibility into the entire value creation process rather than just their specific tasks. Teams can identify interdependencies and communicate more effectively about potential improvements. The process mapping aspect of VSM analysis creates natural touchpoints for cross-functional project collaboration and problem-solving.

Consider these communication benefits of value stream mapping:

- Creates a unified view of the business process across departments

- Establishes clear handoff points between teams

- Provides a framework for discussing process improvements

- Helps identify communication gaps that slow down workflows

- Builds empathy between teams by showing constraints each group faces

This improved communication leads to faster issue resolution and promotes a culture of continuous improvement through active listening and shared problem-solving.

Expert Insight: Implementing value stream mapping (VSM) enhances cross-functional communication by providing a unified view of business processes, establishing clear handoff points, and identifying communication gaps. This fosters collaboration, accelerates issue resolution, and promotes a culture of continuous improvement through shared understanding and active listening among teams.

5. Data-Driven Decision Making

Implementing VSM analysis transforms how organizations approach decision-making by providing concrete metrics for evaluating process performance. When you conduct a thorough value stream mapping exercise, you collect valuable data points that expose inefficiencies and highlight improvement opportunities. This approach allows businesses to move beyond gut feelings and embrace fact-based strategies.

VSM analysis delivers quantifiable insights about throughput rates, cycle times, and resource utilization across your workflow. These metrics create a foundation for calculating potential ROI on process changes before implementation. For example, you can accurately estimate how reducing setup time by 15% might impact overall production capacity.

The data gathered through VSM analysis also supports:

- Performance tracking against industry benchmarks

- Identification of specific process steps causing delays

- Quantification of waste in terms of time and resources

- Validation of improvement hypotheses through measurable outcomes

By leveraging the analytical power of value stream mapping techniques, your organization can make confident decisions backed by solid evidence rather than assumptions. This data-driven approach helps secure buy-in from stakeholders who might otherwise resist change without seeing clear risk-reward calculations.

Expert Insight: Leverage value stream mapping (VSM) to enhance data-driven decision making. By collecting key metrics on process performance, businesses can identify inefficiencies, estimate ROI, and support change initiatives with concrete evidence. This approach not only drives internal confidence but also secures stakeholder buy-in for transformative improvements.

“`html

6. Better Resource Allocation

Conducting a thorough VSM analysis allows you to optimize how resources are distributed throughout your organization. By mapping value streams and identifying bottlenecks, you can strategically allocate personnel and equipment where they’ll create maximum impact.

VSM analysis reveals where your team members’ skills are being underutilized or overburdened, allowing for more balanced workload distribution. When implementing process changes after your analysis, you can make informed decisions about capacity planning to prevent resource shortages during critical phases.

Equipment utilization also improves significantly through proper VSM implementation. By identifying machinery that sits idle or operates inefficiently, you can reschedule operations to maximize utilization rates. This optimization extends to:

- Staffing adjustments based on actual process requirements

- Reallocation of equipment to high-value operations

- Redistribution of workload to eliminate bottlenecks

- Identification of training needs to enhance workforce capabilities

When workloads are balanced across processes through effective process optimization methods, you’ll notice smoother operations with fewer delays and better resource coordination. With properly allocated resources, your organization can maintain consistent output while reducing operational costs.

“`

7. Enhanced Customer Value

VSM analysis directly contributes to enhanced customer value by aligning your business processes with actual customer needs. When performing value stream mapping, you can identify which activities truly add value from the customer’s perspective. This customer-centric approach to process improvement ensures that your VSM analysis focuses on what matters most.

Implementing changes based on thorough value stream mapping leads to significant improvements in product and service quality. By eliminating waste and optimizing workflows, you deliver more consistent results that better meet customer expectations. The process optimization methods identified through VSM help streamline operations while maintaining quality standards.

Additionally, VSM analysis reduces delivery times by minimizing delays between process steps. Customers experience faster service, shorter wait times, and more responsive support. These improvements create a competitive advantage as customers increasingly value speed alongside quality. Consider these customer value enhancements:

- Reduced time between order placement and delivery

- Improved product quality through standardized processes

- Enhanced responsiveness to customer feedback and requests

- More consistent service experiences across all touchpoints

Understanding VSM Analysis

VSM analysis (Value Stream Mapping) provides organizations with a powerful visualization technique to identify waste, inefficiencies, and improvement opportunities throughout their operational processes. By mapping the flow of materials, information, and activities, VSM analysis reveals hidden bottlenecks and creates a comprehensive picture of how value is created and delivered to customers.

The Importance of VSM Analysis in Today’s Business Environment

In today’s competitive business landscape, VSM analysis has become essential for organizations seeking operational excellence and sustainable growth. This systematic approach enables businesses to:

- Eliminate non-value-adding activities (reducing costs by 20-30%)

- Decrease lead times (by 20-50%)

- Improve cross-functional communication

- Enable data-driven decision making

- Optimize resource allocation

- Enhance customer value through better quality and faster delivery

Transforming Organizational Effectiveness

VSM analysis transforms organizational effectiveness by creating visibility into complex processes and providing a framework for continuous improvement that directly impacts bottom-line results.