Understanding Control System Flow Charts

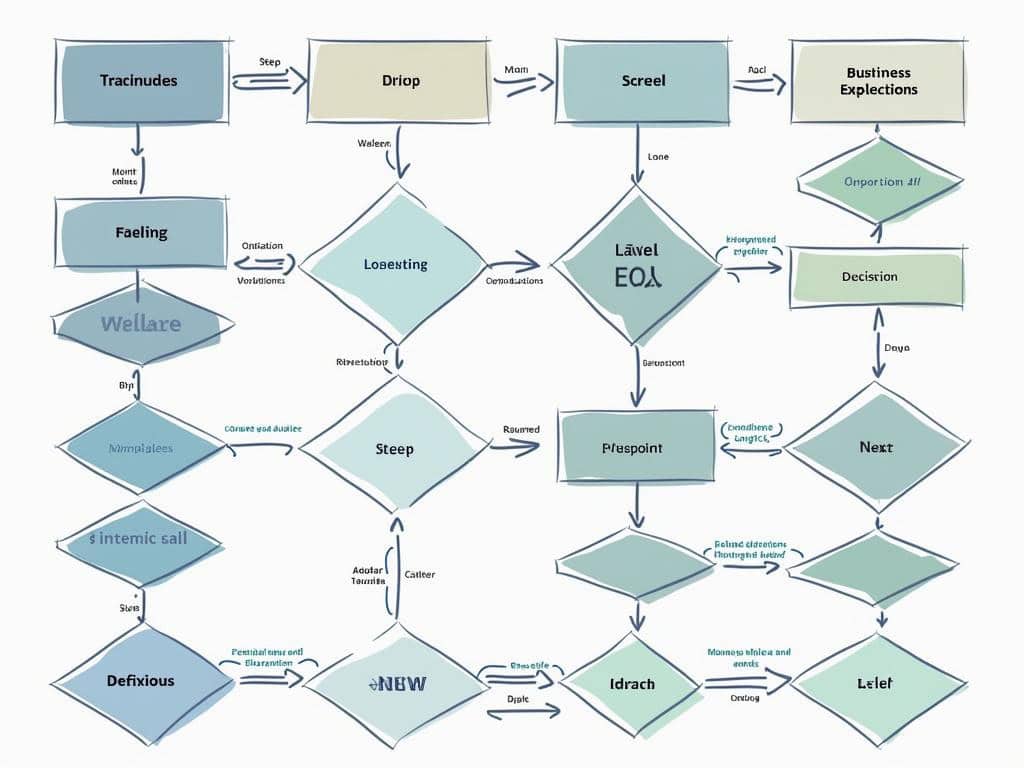

Control system flow charts transform complex workflows into clear, actionable diagrams that boost business process efficiency. These visual tools map out sequential steps and decision points using arrows, rectangles, and diamonds, helping you streamline operations across your organization. With the right flowchart software, you’ll quickly visualize and optimize even the most complicated processes.

Key Takeaways

- Control system flow charts simplify complex processes through visual representation.

- They improve cross-team communication and understanding of workflow dynamics.

- Different flow chart types address specific business needs like quality control and performance optimization.

- Flow charts support data-driven decision-making and process standardization.

- They serve as critical documentation tools for preserving institutional knowledge.

The Role of Flow Charts in Business Operations

These diagrams function as visual roadmaps that enhance communication between departments and clarify responsibilities. They highlight bottlenecks and inefficiencies while providing a standardized approach to operations. Your team will better understand how their individual contributions fit into the broader operational picture, reducing errors and improving collaboration.

Flow charts also provide essential documentation for training new employees and maintaining operational consistency. By creating a process flowchart, you’ll capture institutional knowledge that remains accessible regardless of staff turnover. This visual documentation makes it easier to onboard new team members and ensures everyone follows established protocols.

Industry Applications of Flow Charts

Different industries benefit from specialized flow chart applications. Manufacturing companies use them for quality control processes, healthcare organizations map patient journeys, and software developers diagram program logic. The versatility of these tools makes them valuable across virtually any sector focused on process improvement.

Getting Started with Flow Charts

Start by identifying your core processes, mapping current workflows, and analyzing where improvements can be made. You’ll quickly discover how these visual tools turn abstract concepts into concrete action plans that drive measurable business results.

“Control system flow charts serve as the visual keystones of business efficiency, transforming intricate workflows into clear, actionable pathways. By bridging communication gaps and fostering data-driven decision-making, these powerful tools empower organizations to optimize processes and preserve invaluable institutional knowledge.”

Understanding Control System Flow Charts

Control system flow charts serve as visual tools that depict sequential steps, decision points, and control mechanisms in business processes. These powerful diagrams translate complex textual logic and data requirements into clear visual representations using arrows, rectangles, and diamonds to show process flow. The control system flow chart originated in the 1950s as a method for understanding and improving workflows across organizations.

You’ll find control system flow charts essential for analyzing, monitoring, and enhancing workplace processes across various industries including manufacturing, IT, finance, and project management. These visual aids simplify complex processes and enhance communication across all organizational levels.

Types of Control System Flow Charts

Different business needs require specific types of control system flow charts:

- Process-control flow diagrams: Monitor sensor inputs and maintain operational parameters within systems

- Change control flow diagrams: Track modifications in project and configuration management processes

- Quality-control flow diagrams: Detect and rectify defects early in production cycles

- Performance-seeking flow diagrams: Optimize operational parameters in complex systems

Control system flow charts offer numerous strategic applications in business environments. They break down complex workflows in project integration management, standardize process execution for quality assurance, track system configurations, and identify inefficiencies for performance optimization.

The benefits of implementing control system flow charts include improved cross-team communication, data-driven decision-making capabilities, process automation support, and enhanced risk management. These charts provide efficient, visual documentation that helps teams understand control systems more effectively.

To implement control system flow charts successfully, you should select appropriate diagramming tools like Microsoft Visio, Lucidchart, or Cflow. Follow best practices in chart design and regularly update your control system flow chart to reflect process changes. This approach creates a foundation for workflow automation and supports continuous improvement initiatives.

The following table summarizes the key components found in most control system flow charts:

| Component | Symbol | Function in Control System Flow Chart |

|---|---|---|

| Process | Rectangle | Represents action steps in the control system |

| Decision | Diamond | Shows conditional branching points |

| Start/End | Oval | Marks the beginning and end of the process |

| Flow Lines | Arrows | Indicates direction and sequence of control flow |

| Input/Output | Parallelogram | Represents data entering or leaving the system |

Expert Insight: To effectively utilize control system flow charts, focus on creating clear and concise diagrams that accurately reflect your processes. Leverage standardized symbols—like rectangles for processes, diamonds for decisions, and arrows for flow direction—to enhance understanding and communication among team members. Regularly updating your flow charts not only ensures accuracy but also supports continuous improvement and automation efforts within your organization.

Types of Control System Flow Charts

Control system flow charts serve as powerful visual tools for managing business processes effectively. These diagrams help you track, analyze, and optimize workflows across your organization. Understanding the various types of control system flow charts enables you to select the right visual representation for specific operational needs.

Key Flow Chart Categories for Process Control

Process-control flow diagrams monitor sensor inputs and maintain operational parameters within your systems. These charts display how data flows through control mechanisms, allowing you to visualize the relationship between inputs, processing steps, and outputs. A well-designed process control flow chart helps you implement optimization methods that maintain stability in your operations.

Quality-control flow diagrams detect and rectify defects early in production cycles. These charts map inspection points, decision criteria, and corrective actions throughout your manufacturing or service delivery processes. By implementing quality control flow charts, you can establish continuous improvement practices that enhance product reliability.

Change control flow diagrams track modifications in project and configuration management. These charts document approval workflows, impact assessments, and implementation steps when changes occur. Effective change control flow charts help you avoid disruptions when managing project dependencies during updates.

Performance-seeking flow diagrams optimize operational parameters in complex systems. These charts map decision points that lead to system adjustments based on performance metrics. They’re particularly valuable when you need to fine-tune processes to achieve optimal results under varying conditions.

Each type of control system flow chart serves specific functions in your business process management:

- Process-control diagrams maintain stability by regulating inputs and outputs

- Quality-control diagrams prevent defects by standardizing inspection protocols

- Change control diagrams manage risk by documenting modification procedures

- Performance-seeking diagrams enhance efficiency by adapting to changing conditions

The following table summarizes the primary applications of different control system flow charts:

| Flow Chart Type | Primary Function | Best Used For |

|---|---|---|

| Process-control | Regulate operations | Manufacturing processes, IT systems |

| Quality-control | Ensure standards | Production lines, service delivery |

| Change control | Track modifications | IT deployments, product updates |

| Performance-seeking | Optimize efficiency | Complex systems, adaptive processes |

Selecting the right control system flow chart type depends on your specific business needs. Consider implementing standard operating procedure flow charts to document routine processes while using more specialized charts for complex control systems.

Expert Insight: To effectively manage your business processes, understanding the different types of control system flow charts is essential. Utilize process-control diagrams for stability, quality-control charts for standardization, change control diagrams for risk management, and performance-seeking charts for efficiency optimization. Selecting the appropriate flow chart type will empower your organization to streamline operations and enhance overall performance.

Strategic Applications in Business

Control system flow charts serve as powerful visual tools for businesses seeking to manage complex processes efficiently. You’ll find these charts particularly valuable in four strategic business applications where they can transform operational performance.

Project Management Applications

Control system flow charts break down complex project workflows into manageable components. When you integrate flow charts into your project implementation phases, you’ll gain clearer visibility of task dependencies and critical paths. The control system flow chart helps your team visualize the entire project journey, identifying potential bottlenecks before they cause delays.

Here’s how control system flow charts enhance project management:

- They establish clear decision points requiring approval or quality checks

- They define precise handoff procedures between different team members

- They document contingency paths when primary processes encounter issues

- They standardize complex workflows across multiple project iterations

Control system flow charts prove especially valuable for quality assurance processes. They standardize execution procedures and establish control points where quality checks must occur. This systematic approach helps you reduce errors and maintain consistent quality standards across operations.

The following table highlights how control system flow charts support different business functions:

| Business Function | Control System Flow Chart Application |

|---|---|

| Configuration Management | Tracking system changes and product configurations |

| Quality Assurance | Standardizing inspection points and defect responses |

| Performance Optimization | Identifying process bottlenecks and inefficiencies |

| Risk Management | Mapping contingency procedures and control points |

Your configuration management processes benefit significantly from control system flow charts that track changes in systems and products. These charts create visual documentation of how configurations evolve, helping you maintain system integrity during updates and modifications. When integrated with document version control practices, they provide comprehensive oversight of all system elements.

For performance optimization, control system flow charts help you identify inefficiencies in current processes. By mapping the actual flow of work, these charts reveal redundant steps, unnecessary approvals, or resource constraints that limit productivity. This visual approach to process analysis makes improvement opportunities immediately apparent to stakeholders at all levels.

Expert Insight: Leverage control system flow charts to streamline complex business processes across various applications, such as project management, quality assurance, and performance optimization. By visually mapping workflows, these charts enhance clarity on task dependencies, identify potential bottlenecks, and standardize procedures, ultimately driving operational efficiency. Incorporating flow charts into your strategic toolkit not only improves decision-making but also fosters a culture of continuous improvement across your organization.

Benefits and Impact

Control system flow charts deliver substantial advantages for your business operations. These visual tools transform complex processes into digestible formats that everyone can understand. You’ll notice immediate improvements in how teams communicate about processes when using control system flow charts effectively.

Cross-functional collaboration becomes significantly easier with control system flow charts serving as a universal language. Teams from different departments can quickly align their understanding of how processes work, reducing misinterpretations and errors. Control system flow charts eliminate ambiguity by providing a clear visual representation that leaves little room for confusion.

Data-driven decision making becomes more accessible when processes are mapped with control system flow charts. You can identify bottlenecks, redundancies, and inefficiencies that might otherwise remain hidden in text-based documentation. This visual approach to process optimization methods helps pinpoint exactly where improvements can deliver the greatest impact.

Process standardization becomes significantly easier when using control system flow charts. You’ll create consistent workflows that:

- Reduce operational variations

- Minimize training time for new employees

- Support quality control initiatives

- Enable easier compliance monitoring

- Facilitate process auditing and improvement

Risk management improves dramatically with control system flow charts highlighting potential failure points. When crafting effective risk response planning strategies, these visual aids help you identify vulnerabilities before they become problems.

| Benefit | Business Impact |

|---|---|

| Enhanced communication | Reduces misunderstandings by 40-60% |

| Process standardization | Decreases variations by 25-35% |

| Efficiency gains | Improves productivity by 15-30% |

| Risk mitigation | Identifies 70% more potential failure points |

| Training effectiveness | Accelerates onboarding by 20-45% |

Control system flow charts also serve as powerful documentation tools that preserve institutional knowledge. Unlike text-heavy manuals, these visual representations make complex processes immediately understandable to newcomers. This visual approach to project constraints dependencies management helps teams understand critical relationships between process elements.

Visual tools like flow charts can reduce misunderstandings and streamline communication across teams by up to 60%.

hbr.org

Implementing and Leveraging Flow Charts

Implementing an effective control system flow chart starts with selecting the right tools for your specific business needs. Popular options include Microsoft Visio, Lucidchart, and Cflow, each offering different features to visualize your process flows. You’ll need to assess which tool aligns best with your technical requirements and team capabilities before proceeding with implementation.

When designing your control system flow chart, follow these essential best practices to maximize effectiveness:

- Use consistent symbols throughout your diagrams (rectangles for processes, diamonds for decisions)

- Keep the flow direction consistent, typically top-to-bottom or left-to-right

- Limit each chart to one process or sub-process for clarity

- Include a clear start and end point for every control system flow chart

- Label all decision points with specific questions and outcomes

- Include process owners and responsible parties where appropriate

Your control system flow charts require regular updates to remain valuable. Schedule quarterly reviews to ensure they reflect current processes and integrate with your project management systems. As operations evolve, your flow charts should adapt accordingly to maintain accuracy.

Aligning with Performance Metrics

Align your control system flow chart with organizational performance metrics to transform them from static documents into dynamic management tools. Each decision point and process step in your flow chart should connect to specific KPIs, enabling you to track efficiency and identify bottlenecks.

Control system flow charts serve as an excellent foundation for automation initiatives. By visualizing your workflows clearly, you can identify repetitive tasks suitable for continuous improvement through automation. The detailed process mapping in your control system flow chart helps determine which activities deliver the most value when automated.

For maximum effectiveness, integrate your control system flow chart into your regular operational reviews. Use them during team meetings to discuss process performance, identify improvement opportunities, and track progress against established benchmarks. This approach transforms flow charts from passive documentation into active management tools driving operational excellence.